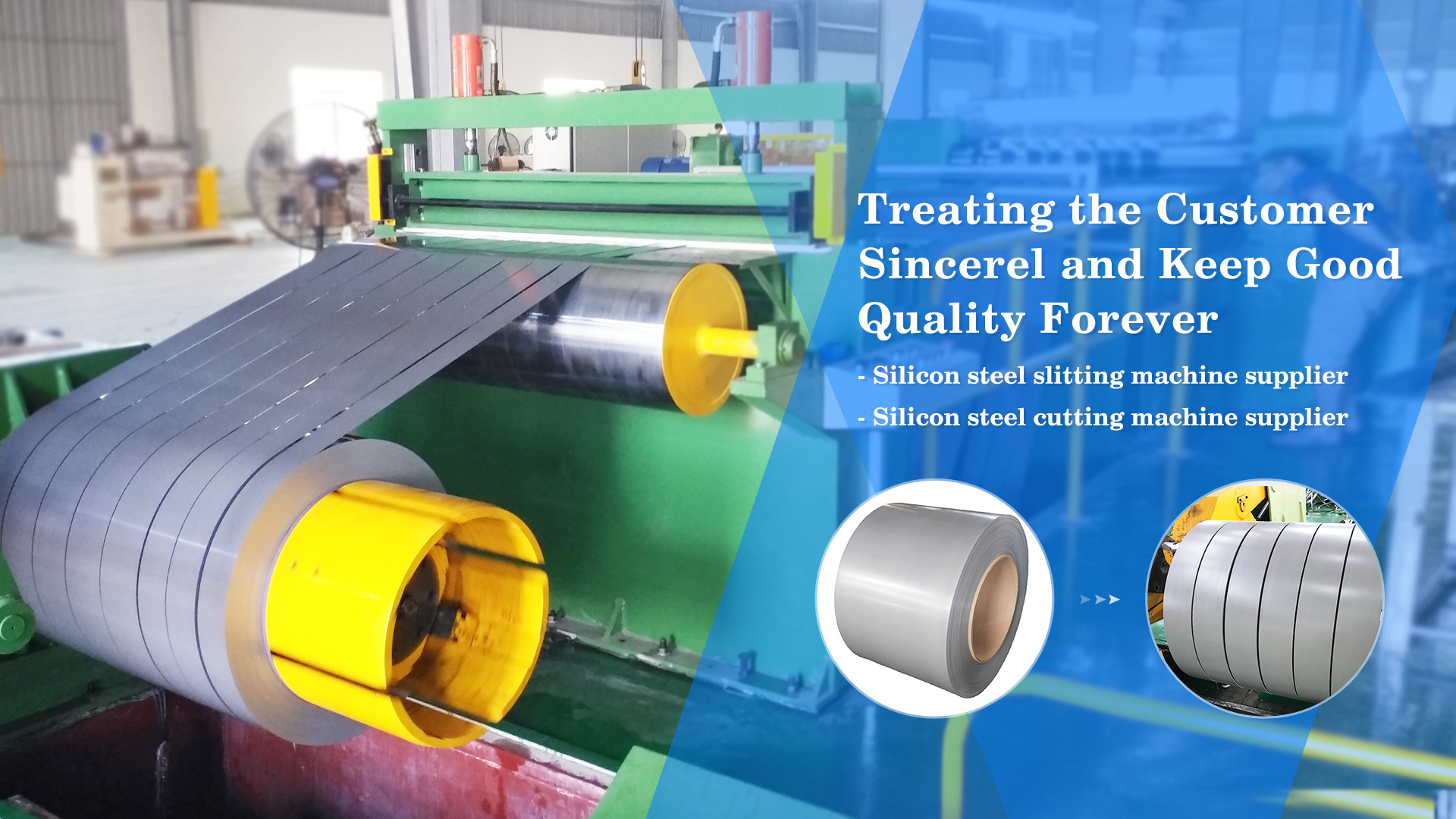

Silicon Steel Slitting Machine

The machines are used to cut the workpieces of the transformer cores.

View moreOur Excellent Products

Its a manufacturing enterprise specializing in the production on CNC horizontal shear and longitudinal cutting machine equipment, and specifically for steel cutting, thin metal forming to design, research and manufacture CNC horizontal and longitudinal cutting machine.

Silicon Steel Slitting Machine

Silicon Steel Cutting Machine

We have Rich Experience

Strong and Guaranteed Strength

01

Exhibition

Based on today's advanced CNC technology and relying on years of expertise...

View more

02

Quality Control

We have a team of professional skills and experience. Precision standard testing equipment...

View more

03

Service

We have over 12 years experience design engineer team, Experienced Installation Engineer Team....

View more

Who are we?

Ruyi Transformer Equipments Manufacturer Co.,Ltd

is a manufacturing enterprise specializing in the production on CNC horizontal shear and longitudinal cutting machine equipment, and specifically for steel cutting, thin metal forming to design, research and manufacture CNC horizontal and longitudinal cutting machine.

Our Latest News

Sep 25,2025

Ruyi Technology has relocated to a new address. We wish you a grand opening and prosperous business.

As the crisp autumn breeze brings a refreshing coolness, we celebrate harvests, promote culture, and revitalize rural communities. On September 23, 2025, the eighth “China Farmers' Harvest Festival” will be observed. To mark this occasion, Jiangsu Ruyi Technology Development Co., Ltd. launched a new chapter with its relocation ceremony and 15th-anniversary celebration themed “Gratitude and Companionship, Smart Manufacturing for the Future” at No. 8 Wenbei Road, Zhutang Beiwang Industrial Park, Jiangyin City. At this new starting point, we will build upon past achievements and join hands to create an even brighter future.

07

2024-05

Trend analysis of domestic transformer industry

In recent years, the power supply of electronic transformers used in the core data and the price of conductive materials continued to decline, the upstream raw materials caused by the seller's market. As a power electronic transformer in the upper reaches of the user, and can choose to sell in the global scale, resulting in a buyer's market. The electronic transformer industry in the middle position, as long as go road renovation skills, ability to shake off the dilemma of both sides. However, in the mature electronic transformer industry, the difficulty of the renovation of the difficult. But every tiny part of the improvement, it will be able to bring new ideas and new products.

08

2024-05

The quality of the longitudinal shear and transverse shear determines the quality of the iron core

After longitudinal shearing and transverse shearing, the silicon steel coils are stacked into iron cores. The quality control of the iron core generally includes punching of various shapes, notches of various shapes, longitudinal shearing of silicon steel sheets and transverse shearing of various plate shapes to control various quality indicators. Next, Ruyi Technology will provide You bring the effect of slitting and shearing on the quality of the iron core.

07

2024-05

Like many electronic devices, transformers are comprised of a multitude of parts, each working in conjunction with the others to ensure the safe and effective transmission of energy. In order to get a better handle on different types of transformers and why they may be suitable for certain applications, it is helpful to examine the various components at work.The core makes up the bulk of a transformer, so it’s no surprise that selecting the proper material plays an integral role in the transformer’s overall function. A range of cores exist, such as steel laminated, solid, toroidal, and air cores, as well as variations of each within their respective categories.